Address Expanded Asset Attack Surface In Manufacturing

Lack of Visibility Into IT, IOT, OT

The convergence of IT and OT environments has created asset visibility challenges. ORDR delivers real-time visibility for every connected asset and cyber-physical system, including IoT and OT at a granular level.

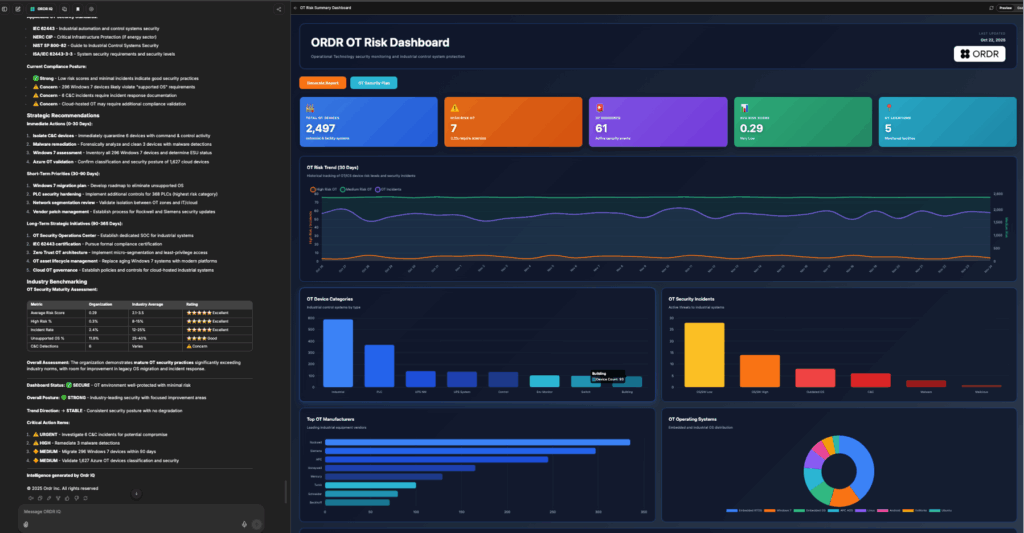

More Threats and Vulnerabilities

Cyberattacks targeting cyber-physical systems can significantly disrupt revenue and manufacturing processes. ORDR identifies exposure, prioritizes vulnerabilities, and detects threats, to secure every asset critical to manufacturing operations.

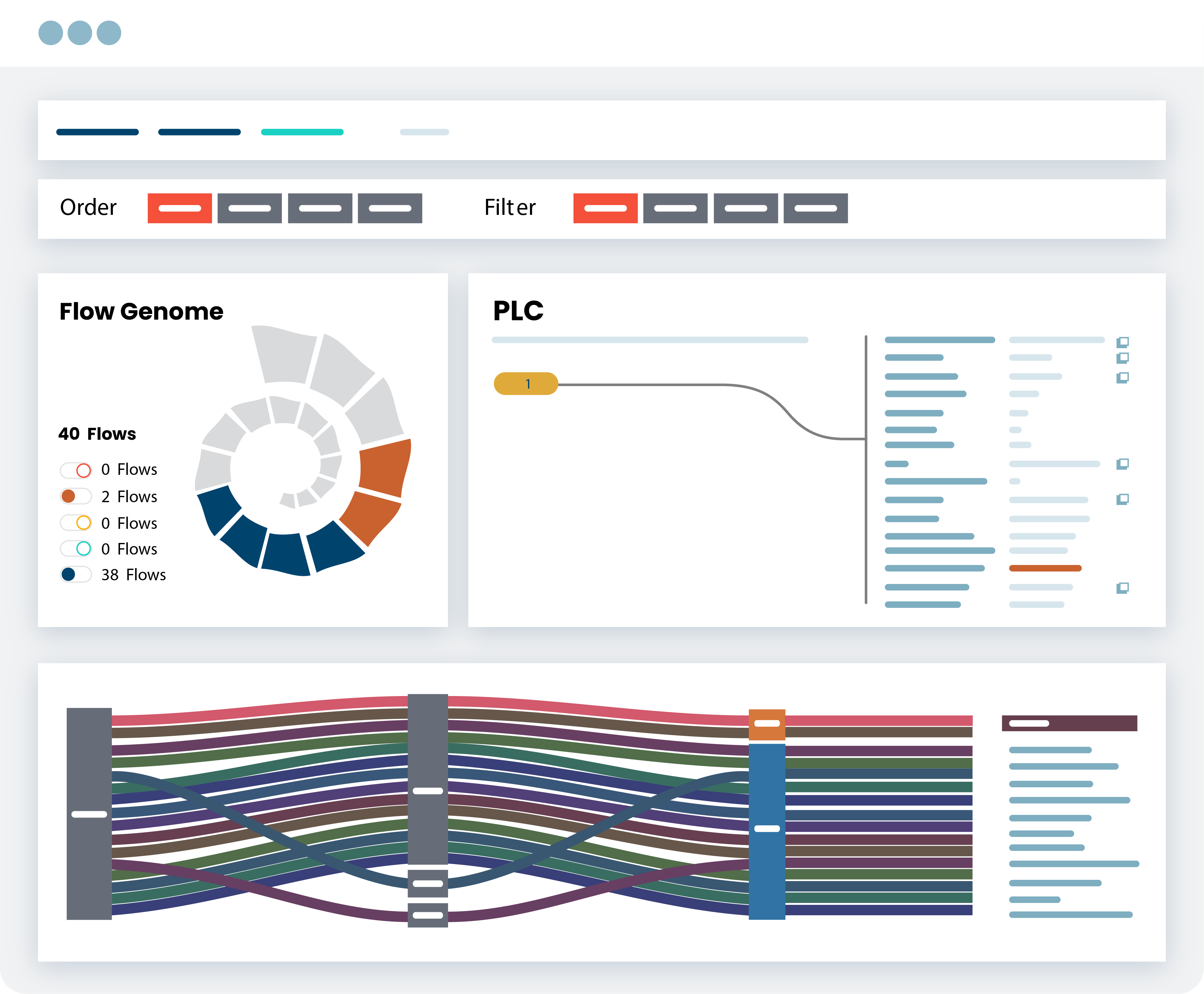

Segmentation Challenges

Traditional air-gapped zones no longer exist. ORDR enables security teams to create segmentation policies based on organizational priorities, for example segmenting critical IOT and OT assets running outdated operating systems, to ensure uninterrupted manufacturing operations.

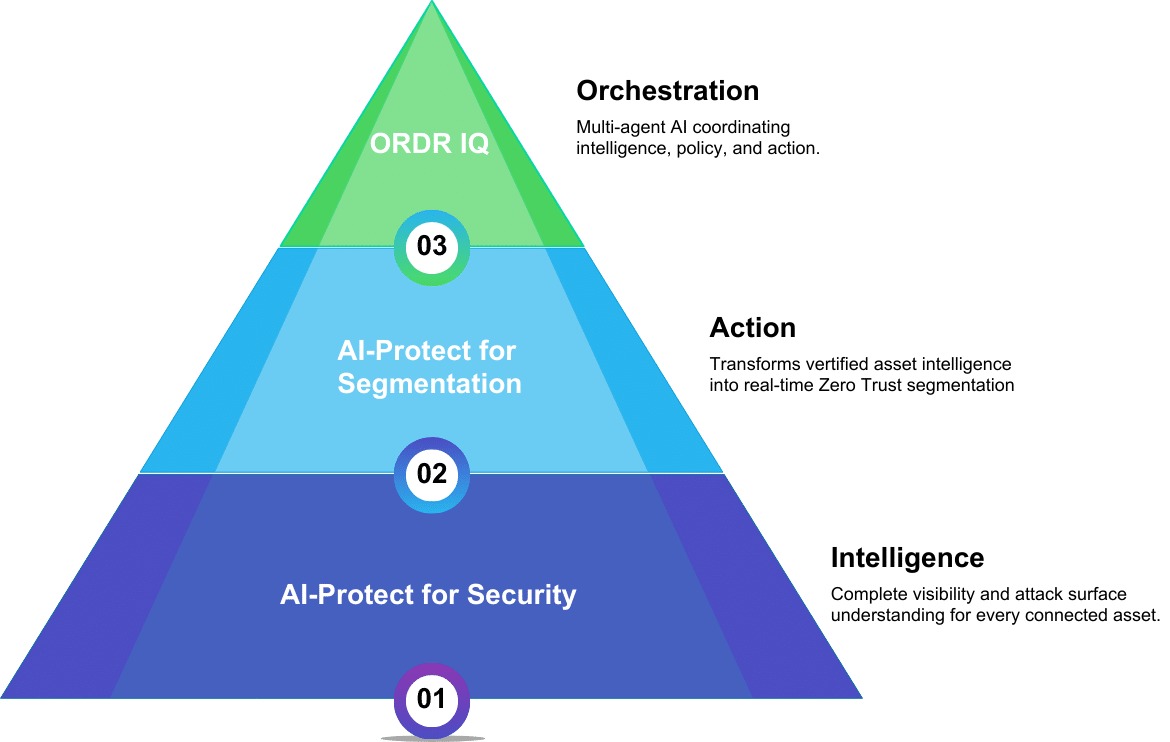

IDENTIFY

See Every Device. Understand Every Risk.

Manufacturing environments rarely lack data; they lack complete, trustworthy awareness across IT, OT, and IoT systems. ORDR brings full, continuous visibility into your entire production ecosystem:

- Automatic discovery of PLCs, HMIs, CNC machines, sensors, robotics, AGVs, quality systems, and IoT devices

- AI-assisted profiling of device identity, firmware, function, and role in the production process

- Baselines built from real traffic and real operational patterns

- AI-driven drift detection that spots changes and unsafe conditions early

- Identification of exposed or misconfigured OT assets before attackers can exploit them to discovery of IoMT, BMS, IoT, and IT devices

Whether on the line, in the warehouse, or in engineering, ORDR shows you what’s connected — and what’s putting uptime at risk.

ENFORCE

Turn Intelligence Into Reliable, Safe Segmentation.

Manufacturers cannot afford disruption. ORDR delivers Zero Trust enforcement built specifically for mixed IT/OT environments — with AI ensuring every enforcement action is safe for production workflows.

- Enforcement powered by real device behavior and operational context

- AI validation that segmentation policies won’t disrupt plant operations

- Prevention of lateral movement from IT into OT networks

- Safe isolation of compromised or drifting devices

- Scalable enforcement across plants, warehouses, and global production sites

- Integration with your existing NAC, firewall, and switching investments

Result: predictable, repeatable, production-safe segmentation — no agents, no downtime, no added complexity.

And the foundation is proven: ORDR’s behavioral enforcement engine is backed by patented innovation originally developed for high-scale, mixed-environment networks.

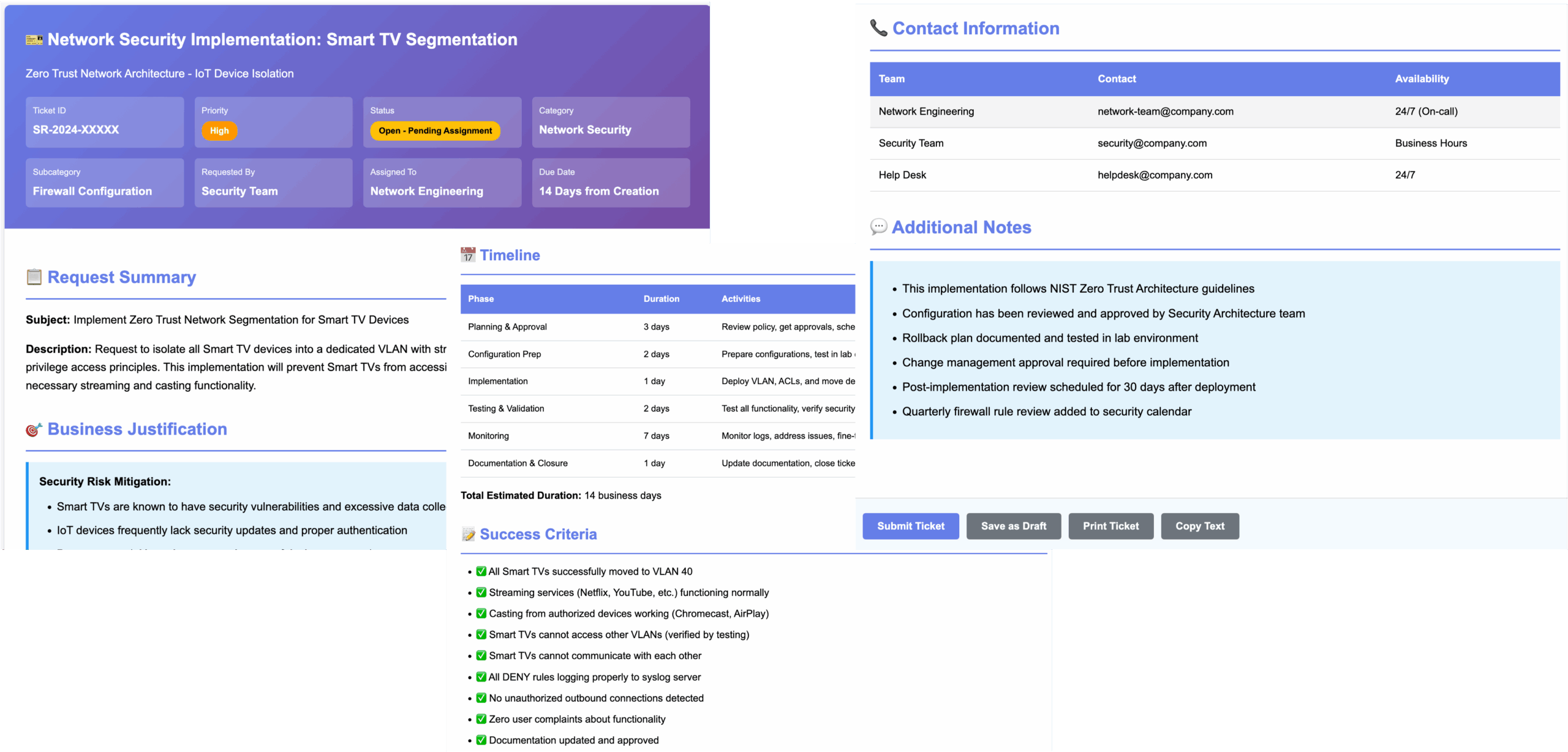

ORCHESTRATE

ORDR IQ — The AI Layer That Makes Your Team Faster.

Manufacturing runs on precision and timing. Every minute of downtime impacts output, revenue, and safety. ORDR IQ accelerates every security and operations workflow by reasoning over ORDR’s real-world telemetry, OT behavior models, and historical device knowledge.

What ORDR IQ can orchestrate:

- Ticketing & Case Automation

- Segmentation Workflow Automation

- Vulnerability & Incident Response Coordination

- Compliance & Audit Documentation

ORDR protects every connected asset from the plant floor to supply-chain operations. ORDR IQ gives your team the speed to outpace threats — not just react to them.

Why Manufacturers Choose ORDR

- Protects uptime with safe, predictable enforcement

- Reduces breach and ransomware risk by stopping lateral movement

- Unifies Security, OT, IT, and Engineering with one trusted view

- Improves audit readiness and supports industry regulations

- Deploys without friction — no agents, no sensors, no production downtime

- Scales globally across multi-site plants and distributed operations